PCB Video

Understanding FR4 Essential PCB Material Properties Applications

Understanding FR4 Essential PCB Material Properties Applications

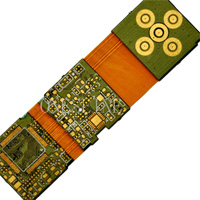

Understanding FR4: The Backbone of Modern Printed Circuit Boards

In the world of electronics, FR4 is more than just a material; it's the fundamental building block for the vast majority of printed circuit boards (PCBs). If you've ever handled an electronic device, from a simple gadget to a complex computer, chances are high you've encountered FR4. But what exactly is it, and why is it so universally popular?

What is FR4?

FR4 is not a single, specific compound, but rather a grade designation defined by the NEMA (National Electrical Manufacturers Association) standards. It refers to a composite material made primarily of:

Woven Fiberglass Cloth: Provides the core structural reinforcement, giving the board its strength and dimensional stability.

Flame Retardant Epoxy Resin: Binds the fiberglass layers together and gives the material its crucial flame retardant properties (the "FR" in FR4 stands for "Flame Retardant", level 4).

This combination results in a rigid laminate sheet that serves as the substrate upon which copper traces are etched to create the electrical pathways of a PCB.

Key Properties & Advantages of FR4:

Excellent Electrical Insulation: Essential for preventing short circuits between copper traces on different layers.

High Mechanical Strength & Rigidity: Provides a sturdy base for mounting components and withstands mechanical stress during assembly and use.

Good Thermal Resistance: Can endure the heat involved in standard soldering processes (typical Tg - Glass Transition Temperature - around 130-140°C). Higher Tg FR4 variants (e.g., 170°C, 180°C) are available for demanding applications.

Flame Retardancy (UL94 V-0): Meets critical safety standards, self-extinguishing and limiting flame spread – a non-negotiable feature for most electronics.

Moisture Resistance: Offers reasonable protection against humidity, though prolonged exposure can degrade performance.

Cost-Effectiveness: Offers an outstanding balance of performance and affordability compared to many alternative high-frequency or exotic substrates.

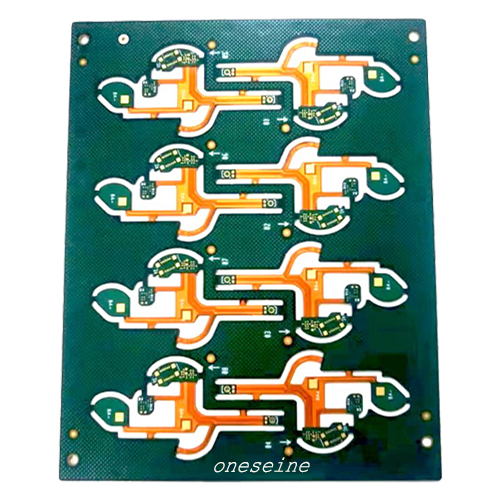

Machinability: Relatively easy to drill, route, and process using standard PCB fabrication equipment.

Wide Availability: The most common PCB material globally, ensuring easy sourcing and established manufacturing processes.

Why FR4 Dominates the PCB Market:

FR4's dominance stems from its ability to hit the sweet spot for a vast array of electronic applications:

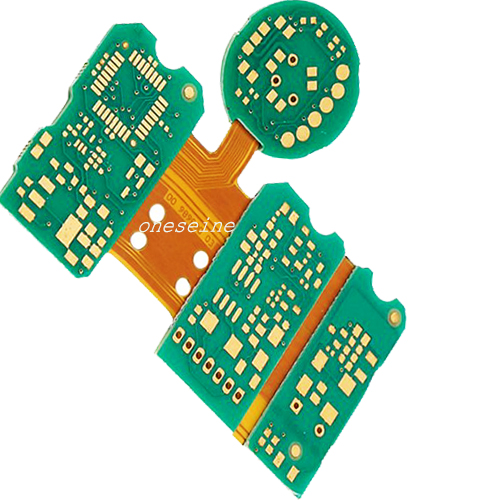

Versatility: Suitable for countless consumer, industrial, automotive, and computing devices where high-frequency performance isn't the primary extreme requirement.

Proven Reliability: Decades of use have cemented its reputation for dependable performance under typical operating conditions.

Manufacturing Ecosystem: The entire PCB supply chain – from laminate suppliers to fabricators to assemblers – is optimized for FR4, keeping costs down and lead times predictable.

Variations of FR4:

Standard FR4 is sufficient for many applications, but specialized variants exist:

High Tg FR4: Withstands higher soldering temperatures (Tg ≥ 170°C), crucial for lead-free (RoHS) assembly and applications experiencing higher operational heat.

Halogen-Free FR4: Uses alternative flame retardants to meet specific environmental regulations (e.g., RoHS 2).

FR4 with Improved CAF Resistance: Designed to mitigate Conductive Anodic Filament growth, a potential failure mechanism in humid environments with high voltage gradients.

Low-Dk FR4: Engineered for slightly better signal integrity where standard FR4's dielectric constant (Dk ~4.4) might be borderline.

Designing with FR4:

While incredibly versatile, understanding FR4's limitations is key for optimal design:

Frequency Limitations: Losses (dissipation factor - Df) increase significantly at higher frequencies (typically above 1-2 GHz), making it less suitable for very high-speed digital or RF applications where materials like Rogers laminates are preferred.

Thermal Management: While heat resistant, FR4 is not a good thermal conductor. Designs with significant power dissipation need careful thermal planning (heatsinks, thermal vias, copper pours).

Moisture Sensitivity: Designs for harsh environments may require conformal coating or selection of variants with enhanced moisture resistance.

Applications of FR4 PCBs:

The list is virtually endless, but includes:

Consumer Electronics (Smartphones, Tablets, TVs, Appliances)

Computers & Peripherals (Motherboards, Graphics Cards, Hard Drives)

Industrial Control Systems

Automotive Electronics (ECUs, Infotainment, Lighting)

Medical Devices (Monitoring equipment, diagnostic tools)

Telecommunications Equipment (Routers, Switches - often lower-speed sections)

Power Supplies

LED Lighting

Conclusion

FR4 is the undisputed workhorse of the PCB industry. Its winning combination of electrical insulation, mechanical strength, flame retardancy, cost-effectiveness, and manufacturability makes it the ideal substrate for the vast majority of electronic applications we rely on daily. While specialized materials exist for niche requirements, FR4's versatility and reliability ensure it will remain the fundamental backbone of electronics manufacturing for the foreseeable future. When you need a robust, dependable, and economical foundation for your circuit board, FR4 is almost always the perfect starting point.

Categories

News

Contact Us

Contact: Flexible PCB

Phone: 0086 18682010757

E-mail: kico@oneseine.com

Add: Main Buliding,No12,Fushan 2th Road,Doumen,Zhuhai,China