PCB Video

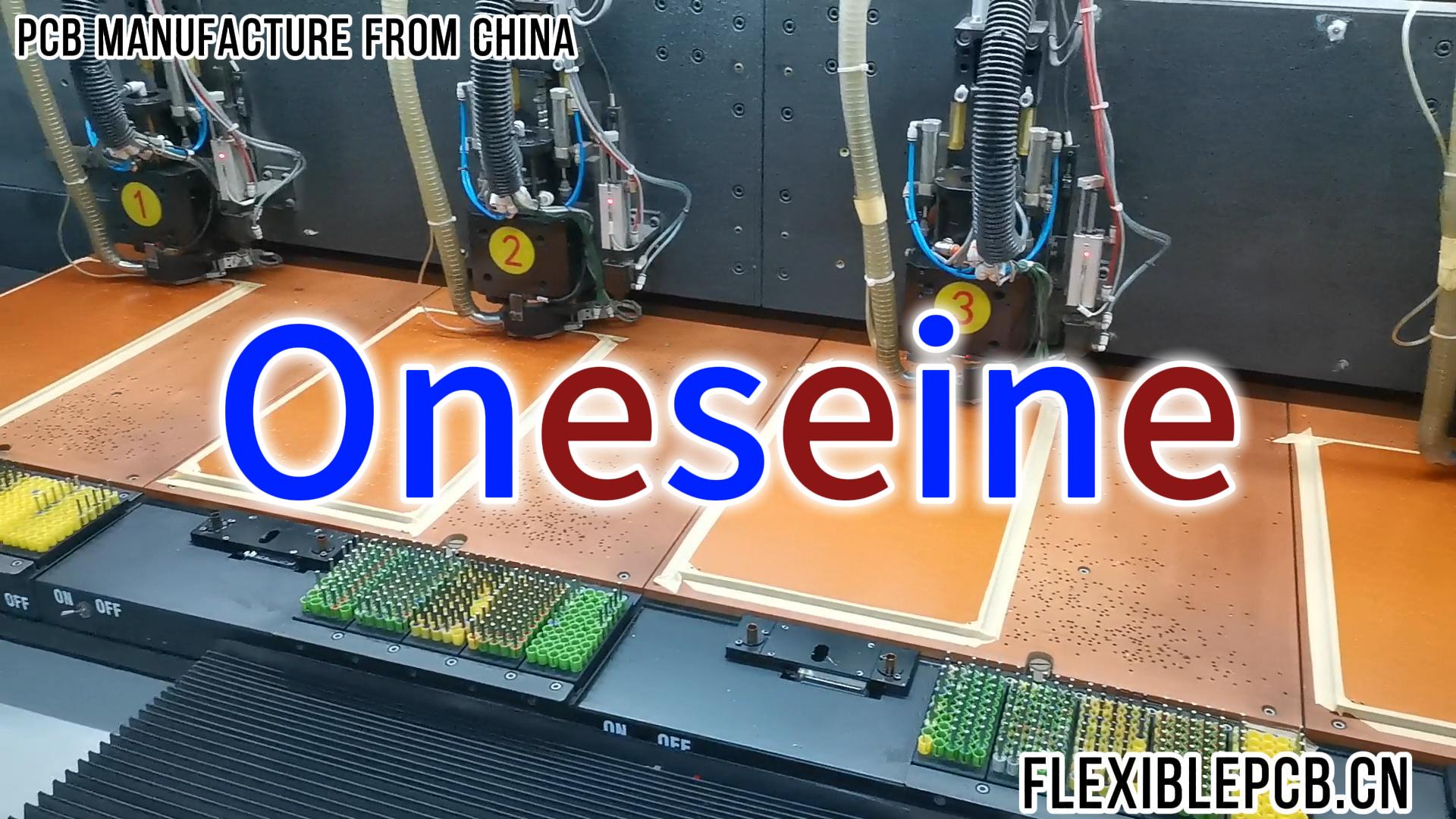

Advanced PCB Manufacturing Equipment,Powering Precision and Efficiency

Advanced PCB Manufacturing Equipment,Powering Precision and Efficiency

In the competitive world of electronics manufacturing, cutting-edge equipment is the cornerstone of producing high-quality printed circuit boards (PCBs). At [Your Company Name], our state-of-the-art machinery and innovative processes ensure unmatched precision, scalability, and reliability for industries ranging from consumer electronics to aerospace. Discover how our advanced equipment portfolio positions us as a global leader in PCB fabrication.

Core Equipment in Our PCB Manufacturing Facility

Our facility is equipped with industry-leading technologies to handle complex designs, high-density interconnects (HDI), and rigorous quality standards:

Laser Direct Imaging (LDI) Systems

Precision: Utilizes UV lasers to create ultra-fine circuit patterns with resolutions down to 15µm, ideal for HDI and microvia designs.

Speed: Reduces photolithography cycle times by 30%, accelerating production for high-volume orders.

Automated Optical Inspection (AOI)

Defect Detection: Advanced cameras and AI algorithms identify microscopic flaws (e.g., shorts, opens, misalignments) in real time.

Yield Optimization: Minimizes scrap rates and ensures 99.9% compliance with IPC-A-600 standards.

High-Speed CNC Drilling Machines

Accuracy: Achieves drill hole tolerances of ±25µm for multi-layer boards, critical for 5G and IoT applications.

Versatility: Supports mechanical and laser drilling for microvias and complex stack-ups.

Vertical Continuous Plating (VCP) Lines

Uniform Coating: Ensures consistent copper deposition across high-aspect-ratio holes, enhancing conductivity and reliability.

Eco-Friendly: Closed-loop systems reduce chemical waste and water consumption by 40%.

Solder Mask Application Systems

Advanced Inkjet Printing: Delivers precise solder mask alignment and thickness control for fine-pitch components.

UV Curing: Ensures rapid hardening, reducing production cycles and improving durability.

Surface Finish Equipment

ENIG (Electroless Nickel Immersion Gold): Provides flat, corrosion-resistant surfaces for high-frequency and RF applications.

OSP (Organic Solderability Preservative): Cost-effective solution for lead-free, RoHS-compliant boards.

Automated Flying Probe Testers

High-Speed Testing: Validates electrical continuity and insulation resistance without custom fixtures, ideal for prototypes and small batches.

Data-Driven Insights: Generates detailed reports for rapid troubleshooting and quality assurance.

Why Choose Our PCB Manufacturing Facility?

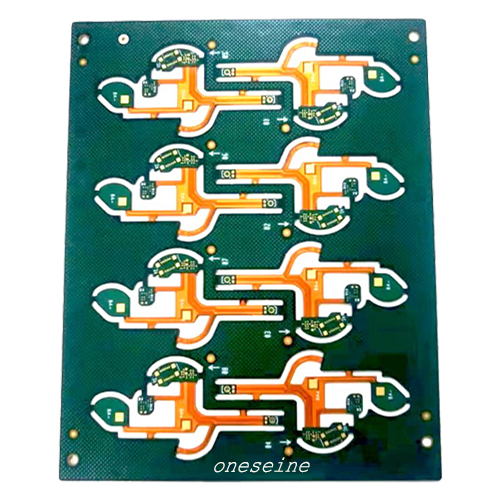

Scalability: From rapid prototyping (<24-hour turnaround) to mass production (10,000+ panels/month), we adapt to your needs.

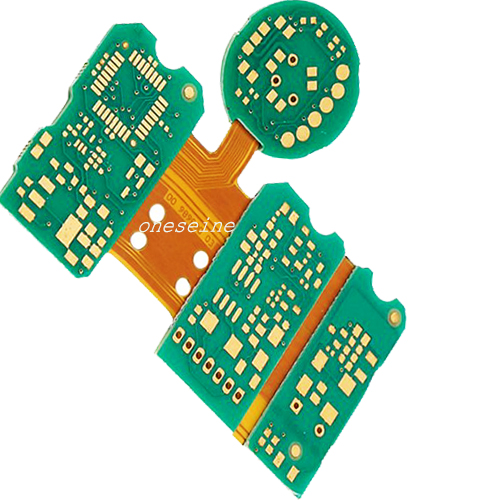

Flexibility: Handle rigid, flexible, and rigid-flex PCBs with layer counts up to 32 layers.

Sustainability: Energy-efficient machinery and ISO 14001-certified processes minimize environmental impact.

Certifications: ISO 9001, IATF 16949 (automotive), and UL-listed manufacturing ensure global compliance.

Industry-Specific Solutions

Our equipment is optimized for diverse sectors:

Consumer Electronics: High-density interconnects (HDI) for smartphones and wearables.

Automotive: Heavy copper boards and thermal management systems for EVs and ADAS.

Medical: Biocompatible materials and ultra-reliable multilayer boards for life-critical devices.

Aerospace: High-frequency laminates (e.g., Rogers, Taconic) for signal integrity in extreme conditions.

Partner with [Your Company Name] for Unmatched PCB Manufacturing Excellence

With decades of expertise and continuous investment in advanced equipment, we deliver PCBs that exceed performance, quality, and durability expectations.

✅ 24/7 Production Monitoring

✅ DFM (Design for Manufacturing) Support

✅ Global Shipping & Logistics

Ready to Elevate Your PCB Projects?

Contact us today to discuss your requirements and experience the difference of working with a technology-driven PCB partner.

PCB manufacturing equipment, advanced PCB machinery, HDI circuit board production, automated PCB inspection, CNC drilling for PCBs, ENIG surface finish, flexible PCB fabrication, high-speed PCB testing, RoHS-compliant PCBs, IoT PCB manufacturing

Categories

News

Contact Us

Contact: Flexible PCB

Phone: 0086 18682010757

E-mail: kico@oneseine.com

Add: Main Buliding,No12,Fushan 2th Road,Doumen,Zhuhai,China