PCB Video

High-Density PCB Drilling Systems: Achieving ±15μm Accuracy for 5G/Aerospace Applications

High-Density PCB Drilling Systems: Achieving ±15μm Accuracy for 5G/Aerospace Applications

Printed Circuit Board (PCB) Drilling Technology

PCB drilling is a critical manufacturing process that creates precise through-holes and vias in circuit boards for electrical connections between different layers. Modern drilling technologies include:

Mechanical Drilling

Utilizes high-speed spindle drills (typically 100,000-300,000 RPM)

Carbide drill bits (0.1mm-6.5mm diameter)

Features automatic tool changing (ATC) systems

Achieves positional accuracy ±25μm

Laser Drilling

Employed for microvias (<150μm)

Common laser types:

UV lasers (355nm wavelength)

CO₂ lasers (9.4-10.6μm wavelength)

Enables blind/buried vias formation

Typical processing speed: 1,000-5,000 holes/sec

Key Technical Parameters

Hole wall roughness: ≤30μm

Aspect ratio: Up to 15:1 (mechanical drilling)

Registration accuracy: ±15μm for HDI boards

Minimum hole size: 50μm (laser) / 100μm (mechanical)

Advanced Features

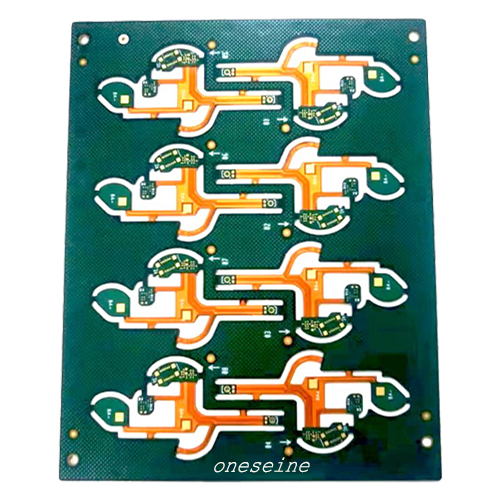

Automatic X-ray alignment for multilayer boards

Real-time depth control for backdrilling applications

Dust extraction systems with vacuum pressure > 65kPa

Vision-assisted alignment systems with CCD cameras

Material Considerations

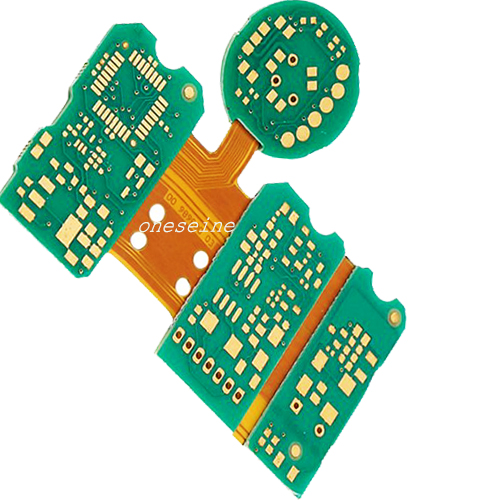

Optimized parameters for FR-4, Rogers, polyimide substrates

Specialized treatments for copper-clad laminates

Heat-affected zone (HAZ) control in laser processing

Quality Control

Automated optical inspection (AOI)

Cross-section analysis for plating quality

Electrical continuity testing

X-ray inspection for multilayer alignment

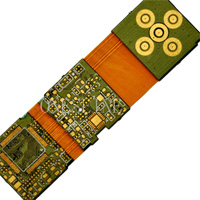

These drilling technologies enable production of high-density interconnects (HDI), multilayer boards (up to 50+ layers), and flexible circuits, meeting requirements for 5G, aerospace, and miniaturized electronics applications.

Categories

News

Contact Us

Contact: Flexible PCB

Phone: 0086 18682010757

E-mail: kico@oneseine.com

Add: Main Buliding,No12,Fushan 2th Road,Doumen,Zhuhai,China