PCB fabrication

High thermal conductivity Fr4 High TG 170 / 180 PCB

High thermal conductivity Fr4 High TG 170 / 180 PCB

Specification:

Material: High TG fr4(S1170,KB6168),Isola optional

Layer:2

Thickness:1.0mm

Copper: 35um

Surface finish: ENIG

Board size: customized

Min line:3mil

Min hole:0.15mm

High Temperature High TG PCB Used In Petrochemical Industry Field

180 ℃ High TG High Thermal Conductivity Kingboard FR4 2 Layer PCB Circuit Board 1.0mm

Fr4 High TG PCB concept:

370HR is a high performance 180°C glass transition temperature (Tg) FR-4 system for multilayer Printed Wiring Board (PWB) applications where maximum thermal performance and reliability

are required. 370HR laminate and prepreg products are manufactured with a unique high performance multifunctional epoxy resin, reinforced with electrical grade (E-glass) glass fabric.

This system provides improved thermal performance and lowexpansion rates in comparison to traditional FR-4 while retaining FR-4 processability.

Tg means Glass Transition Temperature. As flammability of printed circuit board (PCB) is V-0 (UL 94-V0), so if the temperature exceeds designated Tg value, the board will changed from glassy state to rubbery state and then the function of PCB will be affected.

If working temperature of your product is higher than normal (130-140C), then have to use high Tg material which is > 170C. and popular PCB high value are 170C, 175C, and 180C. Normally the PCB Tg value should be at least 10-20C higher than working temperature of product. If you 130TG board, working temperature will be lower than 110C; if use 170 high TG board, then maximum working temperature should be lower than 150C.

Circuit board must flame-retardance , at a certain temperature does not burn, only soften. At this temperature point is called the glass transition temperature (Tg point), this value is related to the PCB dimensional stability.

The higher of TG value, the better of pcb high temperature resistance

High TG PCB material:

Substrate melting from the solid state of the critical temperature of the rubbery fluid, called the melting point of the melting point of Tg 2.Tg points that the higher pressure in the plate when the temperature requirements, the pressure out of the board will be more hard and brittle, To the extent that it affects the quality of the mechanical drilling (if any) after the process, and the electrical characteristics when used. 3. The Tg point is the maximum temperature (C) at which the substrate remains rigid. That is to say, ordinary PCB substrate material not only softens, deforms and melts at high temperature, but also shows a sharp decline in mechanical and electrical properties. 4. General Tg sheet is more than 130 degrees, High-Tg is more than 170 degrees , Medium Tg greater than about 150 degrees; substrate Tg increased, printed circuit board heat resistance, moisture resistance, chemical resistance, stability and other characteristics will improve and improve. The higher the TG value, the better the temperature resistance performance of the board, especially in the lead-free HAS process, high Tg applications more

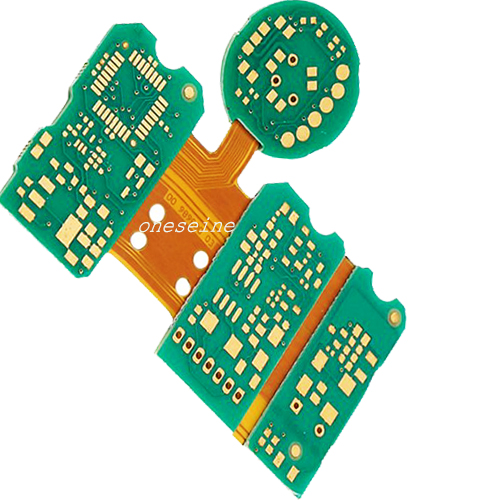

Application:

petrochemical industry,Mine industry

Industrial equipment, GPS, automotive, instrumentation, medical equipment, aircraft, military weapons, missiles, satellites

DC-DC Power Converters,Automotive,Electronics ,High Brightness LED,Power Supply circuit

What is High TG pcb?

In recent years, the demand for the production of high-Tg printed circuit board increased year by year. The following describes the high Tg circuit board in the end what is.

High Tg refers to high heat resistance. General Tg of the plate is more than 130 degrees, high Tg is generally greater than 170 degrees, medium Tg is greater than about 150 degrees, usually Tg ≥ 170 ℃ PCB, called high Tg printed circuit board. With the leap in the development of the electronics industry, especially the computer as the representative of the electronic products, toward a high functional, high multi-layer development, the need for PCB substrate materials, higher heat resistance as an important guarantee. The emergence and development of high-density mounting technology, represented by SMT and CMT, have made PCBs more and more dependent on the high heat resistance of the substrate in terms of small aperture, fine wiring and thinness.

The Tg of the substrate is improved, and the characteristics of heat resistance, moisture resistance, chemical resistance, and stability of the printed circuit board are improved and improved. The higher the TG value, the better the temperature resistance of the sheet, especially in the lead-free process, high Tg applications.

Therefore, the general FR-4 and the high Tg of the FR-4 difference is: in the hot state, especially in the moisture after heating, the material's mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition , Thermal expansion and other conditions there are differences in high-Tg products significantly better than ordinary PCB substrate material.

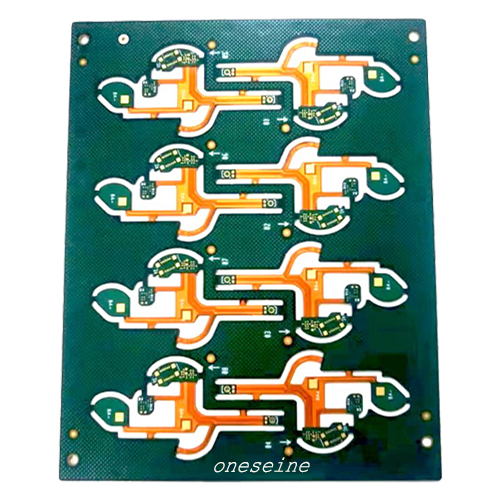

Features:

Excellent heat dissipation, 3-4 times

better than normal FR-4

Excellent thermal and insulation reliability

Superior processability and low Z-CTE

Categories

News

Contact Us

Contact: Flexible PCB

Phone: 0086 18682010757

E-mail: kico@oneseine.com

Add: Main Buliding,No12,Fushan 2th Road,Doumen,Zhuhai,China