PCB fabrication

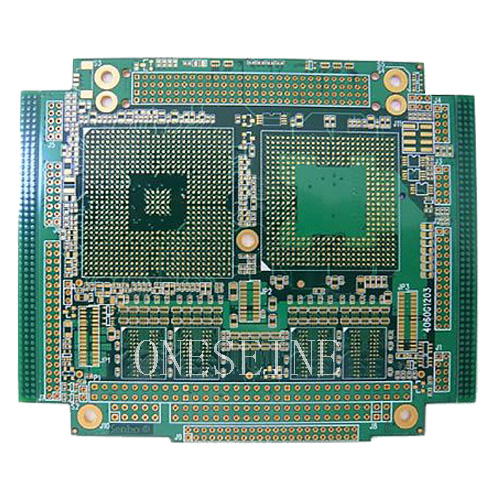

Standard Fr4 Chinese PCB manufacturers TG180 Printed Circuit Boards With BGA

Standard Fr4 Chinese PCB manufacturers TG180 Printed Circuit Boards With BGA

PCB Quick detail:

Material:Fr4

Layer:8

Thickness:1.2mm

Surface finish:Immersion gold

Board size:18*22cm

Application:Communication

Name:Multilayer printed circuit boards

Solder mask:Green

Silk screen:White

Multilayer PCB information:

Top silkscreen/Legend: to identify name of each PAD, board part number, data, etc;

Top Surface finishing: to protect exposed copper from oxidation ;

Top Soldermask (overlay): to protect copper from oxidation, to be not soldered during SMT process;

Top Trace: copper etched according to design to carry on different function

Substrate/Core material: Non-conductive such as FR4

Prereg (PP)

Middle Layers, such as GND, VCC, Inner 3, Inner 4, etc.

Prepreg (PP)

Bottom trace (if any): (same as above mentioned)

Bottom soldermask (overlay):(same as above mentioned)

Bottom surface finishing: (same as above mentioned)

Bottom silkscreen/legend: (same as above mentioned)

More layers it is, more complex & difficult the manufacturing will be, and more expensive the cost will be.

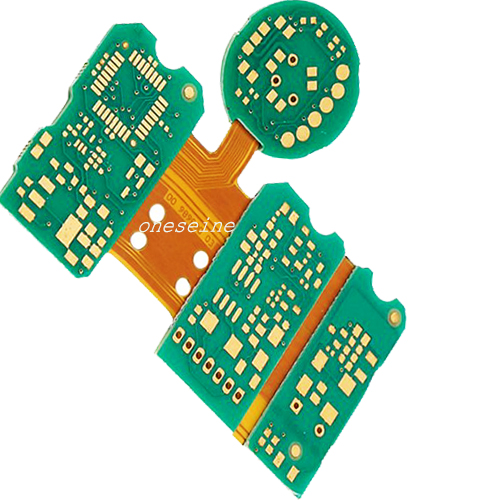

Multi-Layer PCB refer to printed circuit board has more than two copper layers, such as 4L, 6L, 8L, 10L, 12L, etc. As technology improving, people can put more and more copper layers on the same board. Currently, we can produce 20L-32L FR4 PCB.

By this structure, engineer can put trace on different layers for different purpose, such as layers for power, for signal transfering, for EMI shielding, for components assembly, and so on. In order to avoid too many layers, Buried Via or Blind via will be designed in multi-layer PCB. For board more than 8 layers, high Tg FR4 material will be popular than normal Tg FR4.

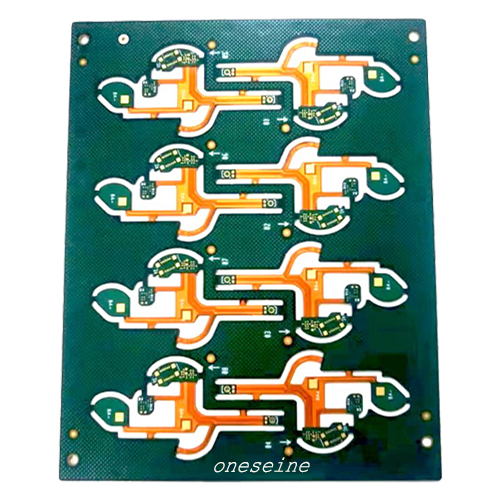

How are multilayer PCBs made?

Alternating layers of prepeg and core materials are laminated together under high temperature and pressure to produce Multilayer PCBs. This process ensures that air isn't trapped between layers, conductors are completely encapsulated by resin, and the adhesive that holds the layers together are properly melted and cured. The range of material combinations is extensive from basic epoxy glass to exotic ceramic or Teflon materials.

The figure above illustrates the stackup of a 4-Layer/ multilayer PCB. Prepeg and core are essentially the same material, but prepeg is not fully cured, making it more malleable than the core.The alternating layers are then placed into a lamination press. Extremely high temperatures and pressures are applied to the stackup, causing the prepeg to "melt" and join the layers together. After cooling off, the end result is a very hard and solid multilayer board.

Categories

News

Contact Us

Contact: Flexible PCB

Phone: 0086 18682010757

E-mail: kico@oneseine.com

Add: Main Buliding,No12,Fushan 2th Road,Doumen,Zhuhai,China