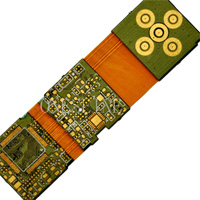

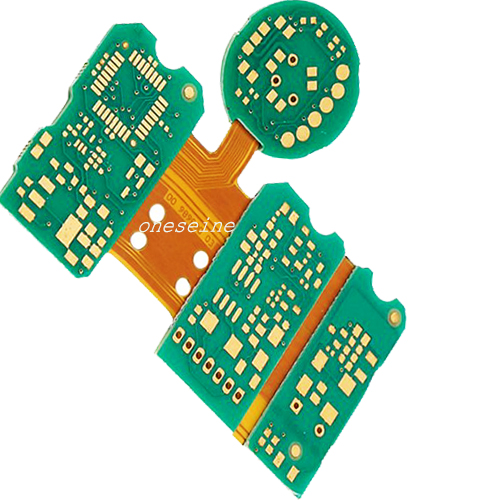

PCB fabrication

Electronic PCBA Manufacturer Industrial Control PCB Fabrication Assembly

Electronic PCBA Manufacturer Industrial Control PCB Fabrication Assembly

Quick Details

Place of Origin:Guangdong, China (Mainland)

Brand Name:ONESEINE

Base Material:FR-4

Copper Thickness:1oz

Board Thickness:1.6mm

Min. Hole Size:0.20mm

Min. Line Width:3mi

Min. Line Spacing:4/4mil(0.1/0.1mm)

Surface Finishing:HASL lead free

Solder mask:Green

Silkscreen:white

Minimun thickness:10um

Tolerance of Impedence Control:5%

PCB standard:IPC-A-610 D

Sample:1PCS also welcome

OEM/ODM:T-SOAR One-stop Service

Certification:ISO-9001,ISO-10041,UL, ROHS

Shipment:DHL UPS TNT FEDEX EMS

Product name:Industrial control PCB assembly

1.Main Production Equipment (8 SMT LINE 3DIP LINE)

ITEM | Device Name | Model | Brand Name | Qty | Remarks |

1 | Full Automatic Screen Printer | DSP-1008 | DESEN | 8 | |

2 | SMT Machine | YG200 | YAMAHA | 5 |

8 SMT Line |

3 | SMT Machine | YV100XG | YAMAHA | 3 | |

4 | SMT Machine | YG100XGP | YAMAHA | 19 | |

5 | SMT Machine | YV88 | YAMAHA | 5 | |

6 | Reflow Soldering | 8820SM | NOUSSTAR | 4 | |

7 | Reflow Soldering | XPM820 | Vitronics Soltec | 3 | |

8 | Reflow Soldering | NS-800 II | JT | 1 | |

9 | Solder Paste Inspection | REAL-Z5000 | REAL | 1 | |

10 | Automatic Optical Inspection System | B486 | VCTA | 3 | |

11 | Automatic Optical Inspection System | HV-736 | HEXI | 5 | |

11 | X-Ray | AX8200 | UNICOMP | 1 | |

12 | Universal 4*48-pindrive concurrent multiprogramming system | Beehive204 | ELNEC | 3 | |

13 | Automatic Plug-In machines | XG-3000 | SCIENCGO | 2 | |

14 | Automatic wave soldering system | WS-450 | JT | 1 | 3 DIP LINE |

15 | Automatic wave soldering system | MS-450 | JT | 2 |

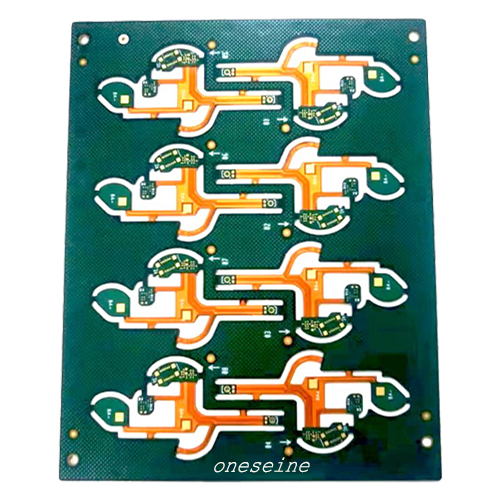

2,PCBA (PCB Assembly) Process Capability:

Technical Requirement | Professional Surface-mounting and Through-hole soldering Technology |

Various sizes like 1206,0805,0603 components SMT technology | |

ICT(In Circuit Test),FCT(Functional Circuit Test) technology | |

PCB Assembly With UL,CE,FCC,Rohs Approval | |

Nitrogen gas reflow soldering technology for SMT | |

High Standard SMT&Solder Assembly Line | |

High density interconnected board placement technology capacity | |

Quote&Production Requirement | Gerber File or PCB File for Bare PCB Board Fabrication |

Bom(Bill of Material) for Assembly,PNP(Pick and Place file) and Components Position also needed in assembly | |

To reduce the quote time, please provide us the full part number for each components,Quantity per board also the quantity for orders. | |

Testing Guide&Function Testing method to ensure the quality to reach nearly 0% scrap rate | |

OEM/ODM/EMS Services | PCBA, PCB assembly: SMT & PTH & BGA |

PCBA and enclosure design | |

Components sourcing and purchasing | |

Quick prototyping | |

Plastic injection molding | |

Metal sheet stamping | |

Final assembly | |

Test: AOI, In-Circuit Test (ICT), Functional Test (FCT) | |

Custom clearance for material importing and product exporting | |

Other PCB Assembly Equipments | SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4 |

Reflow Oven: FolunGwin FL-RX860 | |

Wave Soldering Machine: FolunGwin ADS300 | |

Automated Optical Inspection (AOI): Aleader ALD-H-350B,X-RAY Testing Service | |

Fully Automatic SMT Stencil Printer: FolunGwin Win-5 |

Categories

News

Contact Us

Contact: Flexible PCB

Phone: 0086 18682010757

E-mail: kico@oneseine.com

Add: Main Buliding,No12,Fushan 2th Road,Doumen,Zhuhai,China