Multilayer FPC

Flexible printed circuit manufacturers:Some questions for FPC

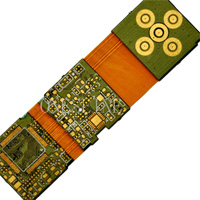

Layer: | 3 | Rigid flex: | flex | Base material: | Copper |

Customize: | yes | Copper: | Rolled copper | Insulation material: | PI |

Thickness: | 0.2mm±0.03mm | Surface | OSP | Flame retardant properties: | VO |

Copper weight: | 1/1(OZ) | Cover film | yellow | Sample test | Flying test |

Three layer flexible circuit board

Product Introduction:

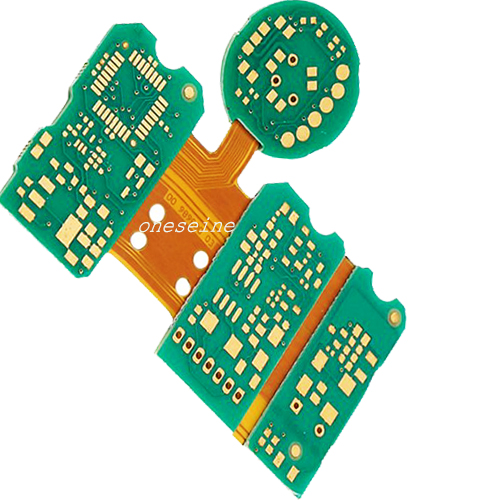

The FPC three-layer board is made by pressing one inner layer and two outer layers, and the surface treatment adopts a high weldability gold deposition process (environmentally friendly). The insulation material is made of polyimide with good flame resistance. This product has a wide range of applications and is suitable for many high-precision and demanding electronic products.

Product Details

1. Substrate

Using non adhesive substrate, the difference between it and adhesive substrate is that its bonding method is to use a hot press to press copper foil and substrate together. Compared to adhesive flexible plates, its flexibility, bonding force between copper foil and substrate, flatness of solder pads, and other parameters are better. But its price is relatively high, usually only used in high demand situations.

2. Copper foil

By using rolled copper foil, the winding performance of the rolled copper foil is better. The unit price of the rolled copper foil is higher than that of electrolytic copper foil, and the molecules of the rolled copper foil are tight and flexible. The thinner the rolled copper foil, the better the flexibility.

3. Insulation material

The insulation material adopts PI, which is generally used as the base film, that is, the base film in the substrate and protective film. PI has the characteristics of high temperature resistance for welding, and its flexibility, dimensional stability, insulation characteristics, heat resistance, electrical and mechanical properties are all very good.

Product Advantages

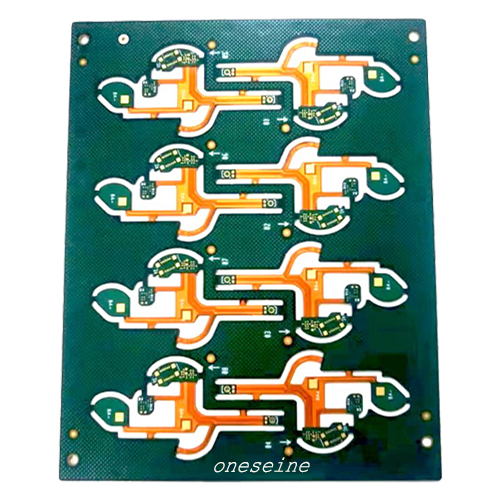

1. Reduce volume

In component assembly, compared to using wire cables, the conductor cross-section of FPC soft boards is thin and flat, reducing the wire size and being able to form along the casing, making the equipment structure more compact and reasonable, and reducing the assembly volume. Compared to rigid PCBs, space can be saved by 60-90%.

2. The end can be soldered as a whole

FPC soft boards, like rigid PCBs, have terminal pads that eliminate wire stripping and tin coating, thereby saving costs. Terminal pads can be connected to components, devices, and plugs using immersion soldering or wave soldering instead of manual soldering for each wire.

3. Continuity of processing

Due to the continuous supply of flexible foil sheets in rolls, continuous production of FPC soft sheets can be achieved. This is also beneficial for reducing costs.

FAQ

Q: Is there a price difference between a three-layer flexible circuit board and a four-layer board?

Answer: Hello, the prices for these two types of plate thicknesses are the same.

Q: What is the typical production cycle for three-layer flexible circuit boards?

Answer: Usually around 8 days.

Q: May I ask if the three-layer board can be used for sinking gold to 3 meters?

Answer: Hello, that's fine.

Q: The line width of the three-layer board is only 0.09mm. Can I produce it?

Answer: Yes, our company can produce.

News

Contact Us

Contact: Flexible PCB

Phone: 0086 18682010757

E-mail: kico@oneseine.com

Add: Main Buliding,No12,Fushan 2th Road,Doumen,Zhuhai,China