PCB fabrication

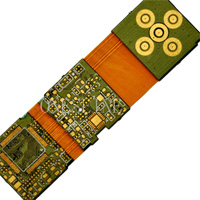

Multilayer Types Fr4 PCB 1.6mm Thickness printed circuit board design and fabrication

Multilayer Types Fr4 PCB 1.6mm Thickness printed circuit board design and fabrication

Quick detail:

Layer:6

Material:FR4

Surface finish:HASL Lead free

Copper weight:1OZ

Board size: 12*17CM

Max board size:60*110CM(withour solder mask)

Solder mask color: green,blue,red,yellow,purple,black,white etc.

Name:FR4 double sided pcb circuit board

Delivery time: fast 24hours, normal 3-5 days

Standard FR-4 Material Properties

》High Glass Transition Temperature (Tg) (150Tg or 170Tg)

》High Decomposition Temperature (Td) (> 325º C)

》Low Coefficient of Thermal Expansion (CTE) ((3.0%-3.8%)

》Dielectric Constant (@1 GHz): 4.25-4.55

》Dissipation Factor (@ 1 GHz): 0.016

》UL rated (94V-0, CTI = 4)

》Compatible with standard and lead-free assembly.

》Laminate thickness available from 0.005” to 0.125”

Pre-preg thicknesses available (approximate after lamination):

150 Tg FR-4 material is used on all standard PCBExpress Quickturn, ValueProto and all PCBpro Full Feature orders unless another specific material or Tg is called out (PCBpro Full Feature or Custom Quote).

FR4 pcb definition

FR-4 (or FR4) is a grade designation assigned to glass-reinforced epoxy laminate sheets, tubes, rods and printed circuit boards (PCB). FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

"FR" stands for flame retardant, and denotes that safety of flammability of FR-4 is in compliance with the standard UL94V-0. FR-4 was created from the constituent materials (epoxy resin, woven glass fabric reinforcement, brominated flame retardant, etc.) by NEMA in 1968.

FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength. The material is known to retain its high mechanical values and electrical insulating qualities in both dry and humid conditions. These attributes, along with good fabrication characteristics, lend utility to this grade for a wide variety of electrical and mechanical applications.

NEMA is the regulating authority for FR-4 and other insulating laminate grades. Grade designations for glass epoxy laminates are: G10, G11, FR4, FR5 and FR6. Of these, FR4 is the grade most widely in use today. G-10, the predecessor to FR-4, lacks FR-4's self-extinguishing flammability characteristics. Hence, FR-4 has since[when?] replaced G-10 in most applications.

FR-4 epoxy resin systems typically employ bromine, a halogen, to facilitate flame-resistant properties in FR-4 glass epoxy laminates. Some applications where thermal destruction of the material is a desirable trait will still use G-10 non flame resistant.

FR4 pcb technology:

Item | Parameter | |

1 | Layer: | 1 to 24 layers |

2 | Material type: | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers |

3 | Board thickness: | 0.20mm to 3.4mm |

4 | Copper thickness: | 0.5 OZ to 6 OZ |

5 | Copper thickness in hole: | >25.0 um (>1mil) |

6 | Max. Board Size: | (580mm×1200mm) |

7 | Min. Drilled Hole Size: | 4mil(0.1mm) |

8 | Min. Line Width: | 3mil (0.075mm) |

9 | Min. Line Spacing: | 3mil (0.075mm) |

10 | Surface finishing: | HASL / HASL lead free, HAL, Chemical tin, Chemical Gold, Immersion Silver/Gold, OSP, Gold plating |

11 | Solder Mask Color: | Green/Yellow/Black/White/Red/Blue |

12 | Shape tolerance: | ±0.13 |

13 | Hole tolerance: | PTH: ±0.076 NPTH: ±0.05 |

14 | Package: | Inner packing: Vacuum packing / Plastic bag,Outer packing: Standard carton packing |

15 | Certificate: | UL,SGS,ISO 9001:2008 |

16 | Special requirements: | Buried and blind vias+controlled impedance +BGA |

17 | Profiling: | Punching, Routing, V-CUT, Beveling |

Application:

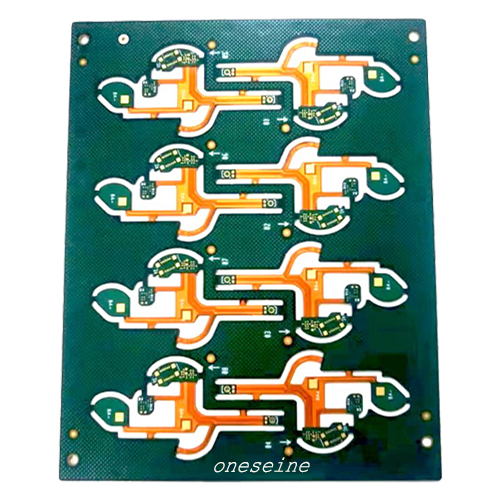

FR-4 is the primary insulating backbone upon which the vast majority of rigid printed circuit boards (PCBs) are produced. A thin layer of copper foil is laminated to one or both sides of an FR-4 glass epoxy panel. These are commonly referred to as per"copperclad laminates."

FR-4 copper-clad sheets are fabricated with circuitry interconnections etched into copper layers to produce printed circuit boards. More sophisticated and complex FR-4 printed circuit boards are produced in multiple layers, also known as "multilayer circuitry".

Specifications

When ordering a copper clad laminate board, the FR-4 thickness and the copper foil thickness must be specified separately.

In the USA, FR-4 thickness is specified in thou or inches, and common thicknesses range from 10 thou (0.010 in, 254 µm) to 3 inches (76 mm).

Copper foil thickness is specified in units of ounces per square foot (oz/ft2), commonly referred to simply as ounce. Common thicknesses are 1 oz/ft2(300 g/m2), 2 oz/ft2 (600 g/m2), and 3 oz/ft2 (900 g/m2). These work out to thicknesses of 34.1 µm (1.34 thou), 68.2 µm (2.68 thou), and 102.3 µm (4.02 thou), respectively. Some PCB manufacturers refer to 1 oz/ft2 copper foil as having a thickness of 35 µm (may also be referred to as 35 μ, 35 micron, or 35 mic).

Other applications

FR-4 is also used in the construction of relays, switches, standoffs, busbars, washers, arc shields, transformers and screw terminal strips.

FR4 PCB classification:

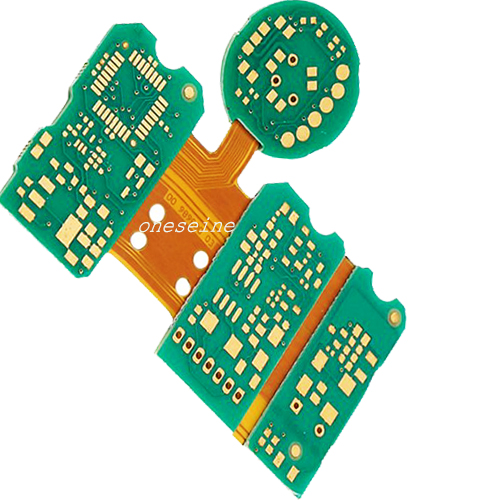

Single sided PCB is the PCB which components centralized on one side, wire centralized on the other side.

Double sided PCB have panel wiring on both sides.

However, to use the wire of the both sides, must have proper circuit connected between them.

This bridge between the circuit is called guide hole (via).

Guide hole is full of or coated metal on the PCB, it can be connected to the wire on both sides.

Because the double sided PCB's area is twice of the single sided, and wires can be interleaved with each other (connected around the other side), it is more suitable for complex circuit than single sided PCB.

High TG PCB High Tg FR4 is recommended for applications that require good performance in high operating temperatures. It is also a good choice for PCBs that require additional security for extreme temperature variations. The main applications are telecom and automotive. This laminate type has excellent performance in Pb-free soldering.

Halogen-free FR4

The main applications are telecom and mobile devices, mainly due to environmental reasons. In addition, halogen free laminates are used in applications where toxic smoke is a concern in case of fire, as in building technology. Halogen free laminates also provide good performance in Pb-free soldering. Please note that the properties of different halogenfree laminates can vary significantly from laminate type to another. The values below apply to our current laminate type.

High frequency fr4

More than 1GHZ

High-frequency pcb is a special circuit board, in general, high-frequency can be defined as the frequency of 1GHz or more. Its physical properties, accuracy, technical parameters are very high, commonly used in automotive anti-collision system, satellite systems, radio systems and other fields.

Impedance pcb

Categories

News

Contact Us

Contact: Flexible PCB

Phone: 0086 18682010757

E-mail: kico@oneseine.com

Add: Main Buliding,No12,Fushan 2th Road,Doumen,Zhuhai,China